Partner Products

IRIS 9000+

Baugh and Weedon are proud to introduce the next generation of heat exchanger inspection capability from Iris Inspection Service.

The IRIS 9000 Plus has nearly 200 years of combined field inspection experience incorporated in its design, combined with a strong commitment to quality and a history of innovation.

Advantages of the IRIS 9000 Plus include:

- Very high level of inspection speed

- Detailed reporting capability, tube sheet maps, colour coding

- Instant decisions possible based on fast report generation

- Automatic or manual pit sizing

Overview

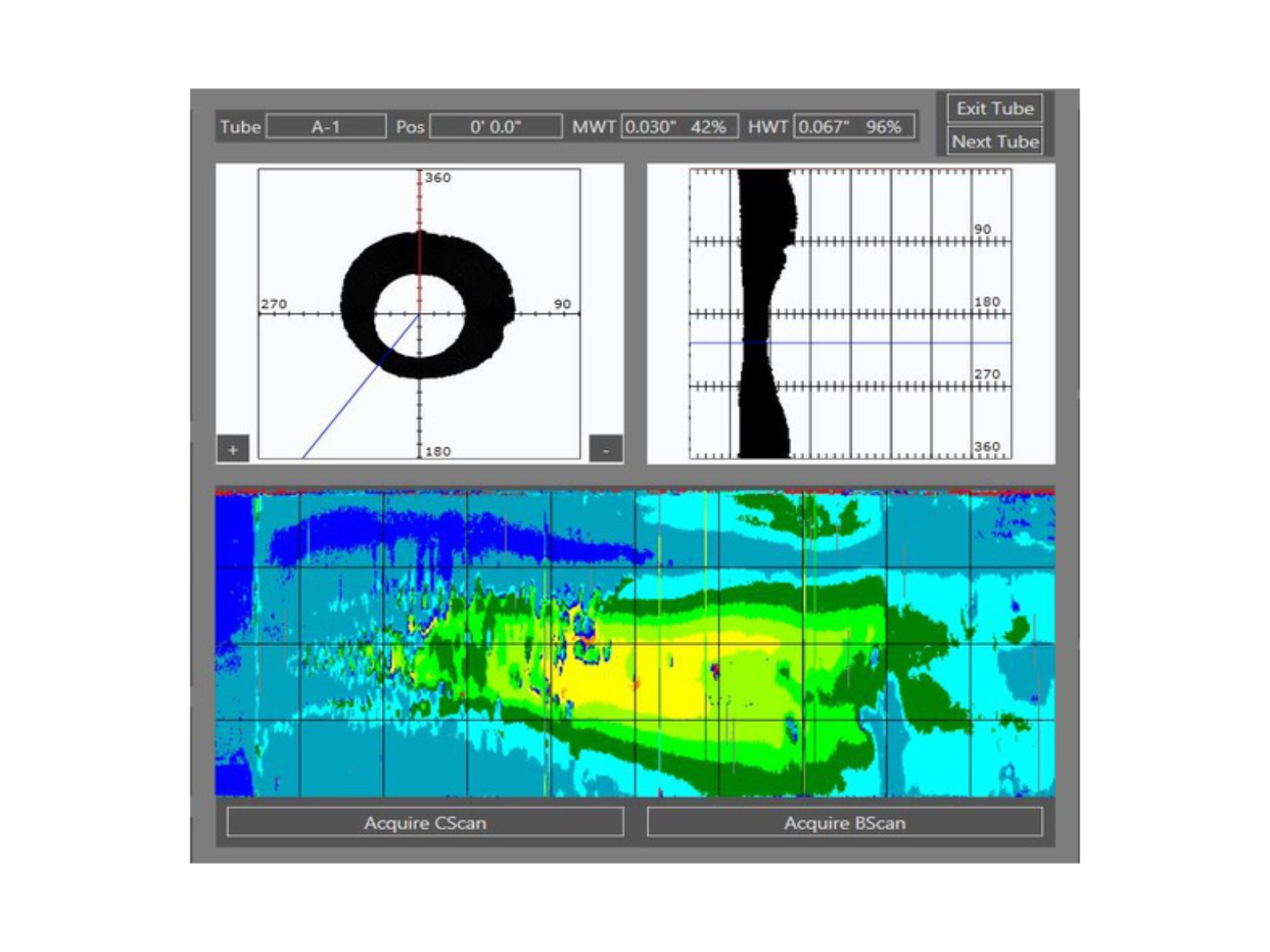

Iris Inspection Services® are the undisputed leader in IRIS technology, combining cutting-edge ultrasonic imaging technology and field proven reliability with unparalleled customer support. This next generation delivers high levels of performance with inspection speeds up to 5 times as fast with real-time C-Scanning and advanced inspection/reporting software.

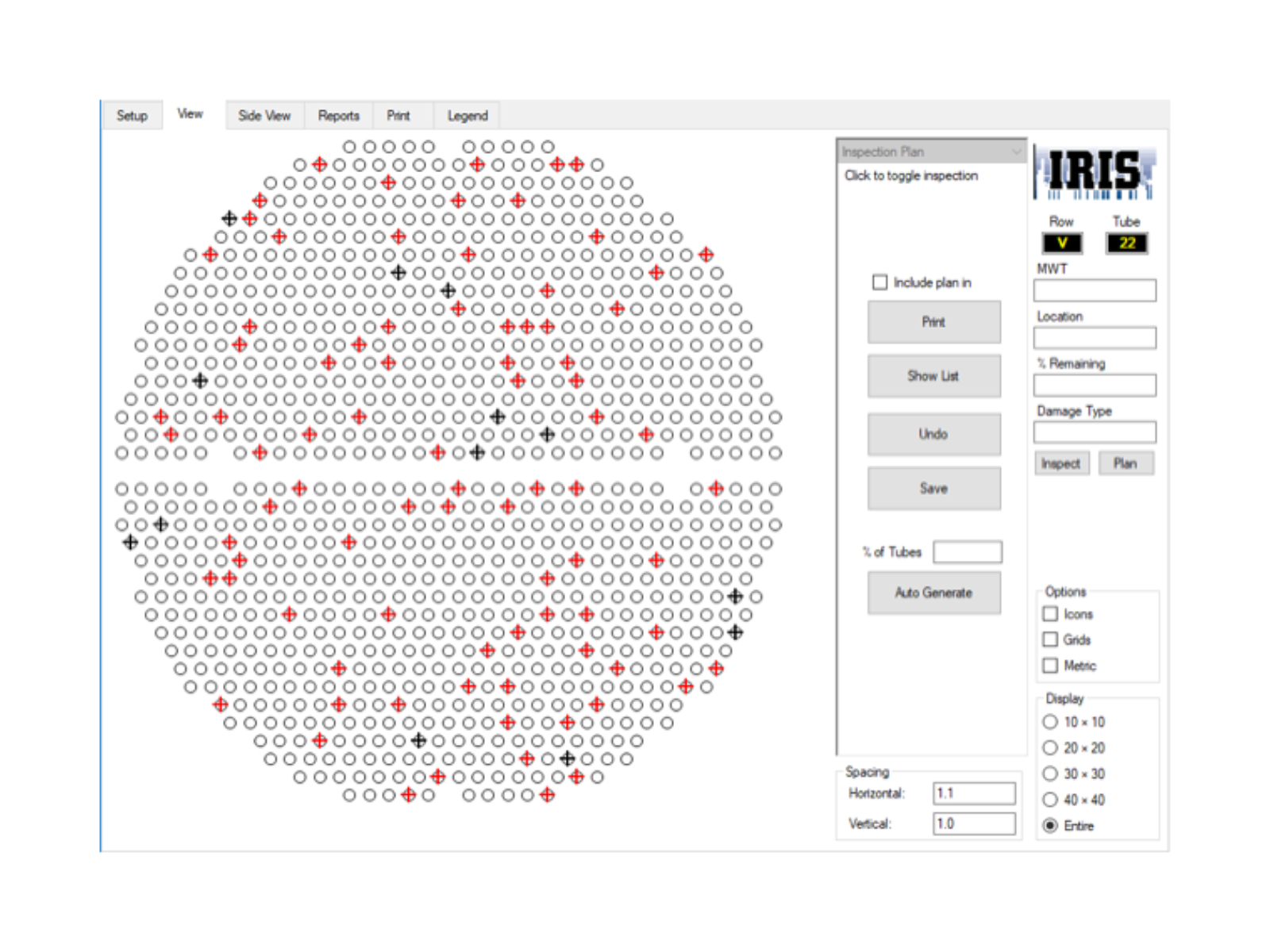

New IRIS-Vision 5.0© software: the complete IRIS control system and reporting application. With this advanced proprietary software; build tube sheet maps and inspection plans, collect and analyse data, and build quick and concise reports – all on-site. This software is used for the inspection, data collection, and analysis. Once complete, an on-site final report is immediately generated. This report consists of a detailed description of the inspection findings, a summary of the test results, tube sheet maps; colour coded by percentage loss/remaining and damage type, side views of the exchanger indicating percentage loss/remaining, detailed information on each tube inspected, along with screen captures of the typical indications found.

Download our brochure:

iris9000.pdf (3.3MB)

Features

- Real-time B and C-Scanning

- Designed for Heat Exchanger inspection, Fin-Fan air coolers, Boilers, Condensers & Chillers

- Rugged, but for performance in hazardous areas

- Use defined alarm limits

Specification

| Channels | 1 pulse echo |

|---|---|

| Pulse Voltage | 200-300 V |

| Bandwidth | 48 MHZ |

| Transducer Frequency | 15 MHZ |

| Maximum Pulsing Rate | up to 13 kHz |

| A-Scan Length | scalable 255 points |

| Turbine Speed | up to 200 rps |

| Min Wall Thickness | 229mm (0.009") |

| Max Wall Thickness | 35mm (1.380") |

| Probe Recognition | AUTO |

| Hardware Monitoring | continual calibration, improved fault & probe monitoring |

| Encoder | quadrature |

| Remote | drive motor direction & speed control |

| Syncing | improved synching, auto adjust to turbine speed |

| Interface (Dual) | Hardware or software control |

| Chassis | rugged reinforced and braced aluminum |

| Dimensions | 31 cm Lx 26 cm W x 17cm H 7kg |

| Temperature Range | -18°C to 46°C (0°E to 11505) |

| Input Voltage | 100-240v • 50-60- |

| Software | |

| Realtime Views | B- and C-scan realtime MW readings, image and control settings recorded, user defined alarm limits |

| Setup Display | B-Scan |

| Profilometry | wall thickness, minimum wall |

| Display | thickness, adjustable cursor and color coded |

| Cursors | cross-section cursors: auto or manual pit sizing |

| Measurement | wall remaining, wall loss and percentages |

| OS | Windows 10 |

| Inspection Plans | manual or auto-generated |

| Reporting | on-site report generation including tube sheet maps, exchanger side view, B- and C-scan screen captures and more |

Related Products