Magnetic Particle Inspection

SBU

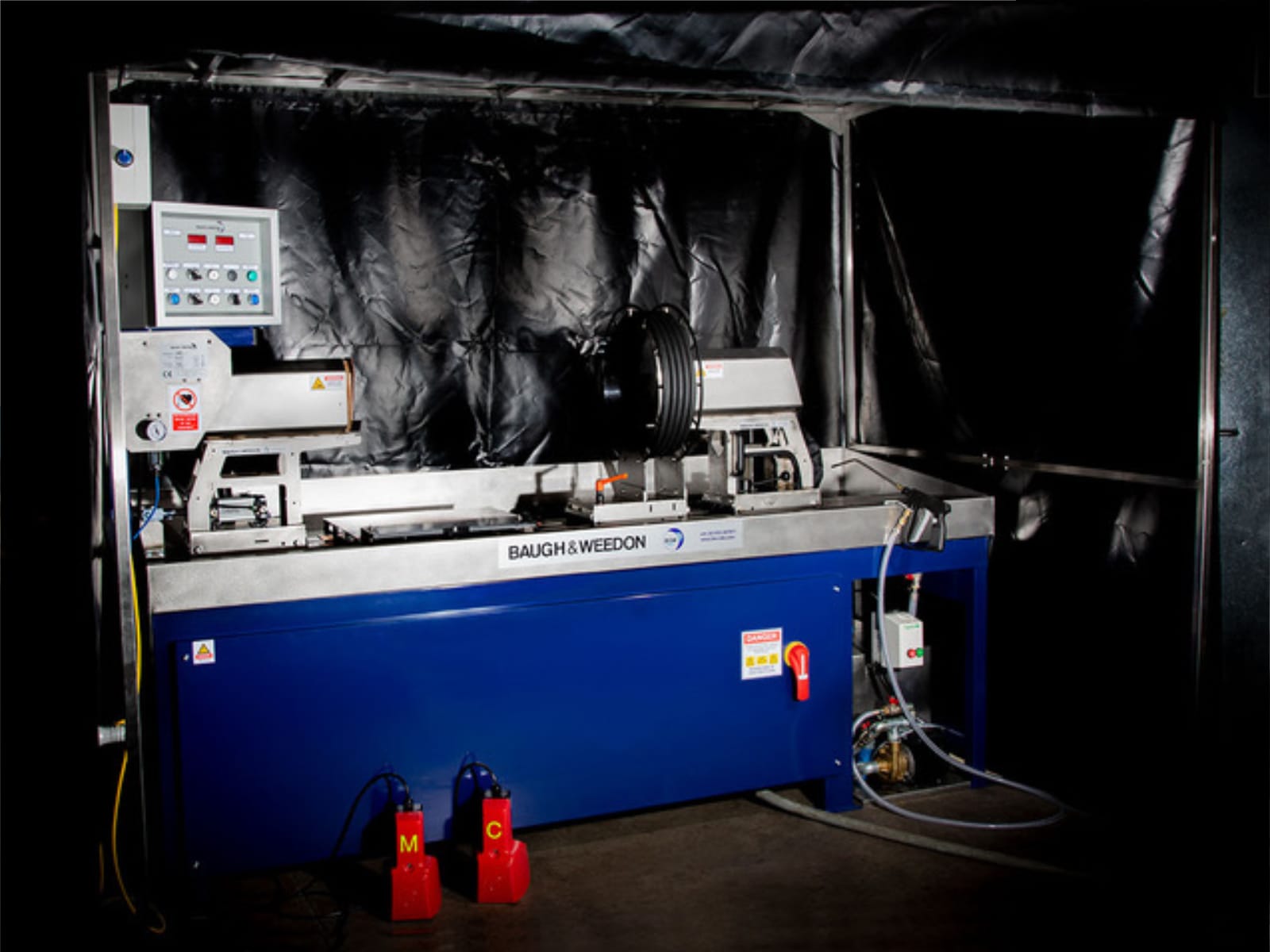

Designed and produced in Hereford, UK, the MAGAZON Bench series offers MPI solutions for the testing of components, of all sizes, that require substantial magnetising currents.

Our MPI benches are available in standard sizes, but built to your specifications; with a wide range of magnetising modes and current waveforms, supported by a full range of accessories and ancillary equipment from Baugh and Weedon.

Advantages of our Standard Benches (SBU) include:

- Stainless Steel Construction

- Built-in memory for up to 99 sets of test parameters

- Current Pre-Selection (CPS) available on all benches

- Various coil options including encircling, pancake and split

- Control Panels built to fit with your inspection process

- Suitable to use with water-based and kerosene inks

- Inking Systems available

- MAGLink2 option: enables PC Control of the MPI bench, enhancing procedural control

Overview

The SBU MAGAZON series of MPI benches have a proven track record for reliability and durability, and are in daily use by most of the leading UK Aerospace companies, offering operators 1000 Amps, 2000 Amps or 2500 Amps.

The Magazon SBU MPI Bench is fitted with a stainless steel drain tank, incorporating the fixed position headstock and moveable tailstock. The on-board power pack is mounted underneath, encased in a heavy duty steel cabinet. The cabinet itself is fitted to a steel plinth which means the whole bench can be moved and relocated with a fork lift truck.

Clamping pressure on the Magazine SBU Bench can be adjusted, delivering the protection of delicate components. A “small component fitting” can also be installed, which enables the rotation of smaller components for easy viewing. For heavier test pieces support rollers mounted on the bed bars are available. For the Magazon SBU, a nominal 2500A power pack provides AC, with HWDC (half wave rectified) and single phase, other options are available ; or 3-phase FWDC (full wave rectified) waveforms as options.

Control panels are designed to reflect your application, with buttons being assigned to work in conjunction with your inspection process needs. Digital metering is standard on all units and can be calibrated to display the output current in PEAK, RMS, or 2xMEAN. Two meters are provided, one meter displays HEAD current and the other displays FLUX/COIL current.

The MAGAZON Series is suitable for use with either kerosene or water based magnetic particle inspection inks.

Download our brochure:

Magazon-SBU (1.3MB)

Features

- Nominal 2500 Amp AC integral power pack

- Current flow and encircling coil magnetising

- 300 mm internal diameter coil

- Pneumatic clamping with footswitch operation

- Digital metering

- Automatic demagnetising using AC decay

- Thyristor current control with current pre-selection

- Preset shot time

- 50L Free standing stainless steel reservoir with pumped ink recirculation

- Control console mounted above the headstock

- Built-in memory for up to 99 sets of test parameters

- Current Pre-Selection (CPS) available on all benches

- Various coil options including encircling, pancake and split

- Maximum test piece lengths: 600mm, 800mm, 1200mm

Videos

Standard Kit

-

SBU Bench - Standard Build or designed to meet your specification.

Options

- Selectable shot time 1, 2 and 3 seconds

- Half wave rectified current (HWDC) waveform

- Flux flow magnetising using single phase FWDC

- Variable transformer current control (sinusoidal waveform)

- Multi-directional magnetising thyristor control AC waveform

- Multi-directional magnetising thyristor control AC and HWDC waveforms

- Low current option, down to 100Amps

- Footswitch for remote magnetising

- E-Stop. Cat-0, electrical cut off with safe control of air supply.

Options for production lines with a high volume of components:

- Multi-directional magnetising or “Swinging Field”

- Automatic Sequencing

- Automatic inking

Specification

| Standard Models | Options & Alternatives | |

| Power Pack | AC waveform with rated output current of 2500A (RMS) | HWDC (half wave rectified) and single phase FWDC (full wave rectified) waveforms |

| Current Flow Magnetising | Max output nominal 3500 AC (peak), measured through a standard shunt | Max output nominal 2500 A HWDC (2xMEAN), single phase FWDC 2500 A (MEAN), 3 phase FWDC 2500 A (MEAN) |

| Encircling Coil Magnetising | Carriage mounted, 5 turn, 300 mm ID coil, length 100 mm. Nominal maximum output / centre field strength in an empty coil. 4200 AT AC (RMS). Coil can be parked at either head or tailstock. | Smaller ID coils for clamping between head and tailstock. Option of higher outputs on request. |

| Flux Flow Magnetising | n/a | Head and tailstock integral flux coils powered by single phase FWDC nominal 20000 AT. |

| Multi-Directional Magnetising | n/a | Swinging Field: Simultaneous operation of two magnetising circuits, to produce a “swinging field” or rotating vector. |

| Current Control System | Variable thyristor, with resulting complex waveform. | A variable transformer can be fitted to provide a sinusoidal current waveform. |

| Working Range | Current range: 10% to 100% of maximum output | Extended working range down to 100 AC (RMS) minimum |

| Metering | Digital metering, calibrated to display PEAK or RMS to within 5% over working range to meet customer requirements. | HWDC and FWDC outputs displayed as peak or MEAN to meet customer requirements. |

| Shot Time | Pre-set single shot of 1, 2 or 3 seconds (other timings can be accommodated). | Any shot-time combination can be catered for, including multiple shots. |

| Duty Cycle | Dynamic duty cycle from 20% at maximum output, to 100% at around 900A RMS. | n/a |

| Max “ON” Time | 3 seconds at 20% duty cycle | n/a |

| Demagnetising | Automatic decaying AC DEMAG | On FWDC demag cycle is low frequency, reversing polarity, with current step down to zero. |

| Headstock | Pneumatically operated, manual control. Clamping stroke: 25mm. Contact pads: 100mm x 100mm. | Foot switch operation. Spring incorporated to reduce pressure. |

| Tailstock | Fully adjustable, manual positioning over entire bed length. Manual quick release locking mechanism | n/a |

| Testpiece Support | V-blocks on head and tailstocks | Removable small piece device with manual rotation for components up to 15 mm diameter. Bed bar mounted adjustable support. |

| Inking System | Ink Tank: 50 litre stainless steel (covered) reservoir with recirculating pump, manual application & integral controls. | Automatic inking as part of the automated process sequence. |

| Services: Power Supply | 230V 50 Hz, 1-phase + neutral + earth, current drawn approx 60A 415V 50Hz, 3-phase + neutral + earth, current drawn approx 30A | The multi-directional magnetising option requires 415 V, 50 Hz, 3 phase + neutral + earth: Current drawn approx. 65 max. |

| Air Supply | 6 bar. (FR unit fitted as standard) | n/a |

Specification subject to change without notice.

Dimensions

| Max Testpiece | |||

| Length (mm): | 800 | 1000 | 1200 |

|---|---|---|---|

| Weight (kg): | 25 | 25 | 25 |

| Equipment Dimensions | |||

| Width (mm): | 1400 | 1600 | 1800 |

| Depth (mm): | 650 | 650 | 650 |

| Height to bed bar (mm): | 975 | 975 | 975 |

| Bed to pad centre (mm): | 200 | 200 | 200 |

Related Products