Magnetic Particle Inspection

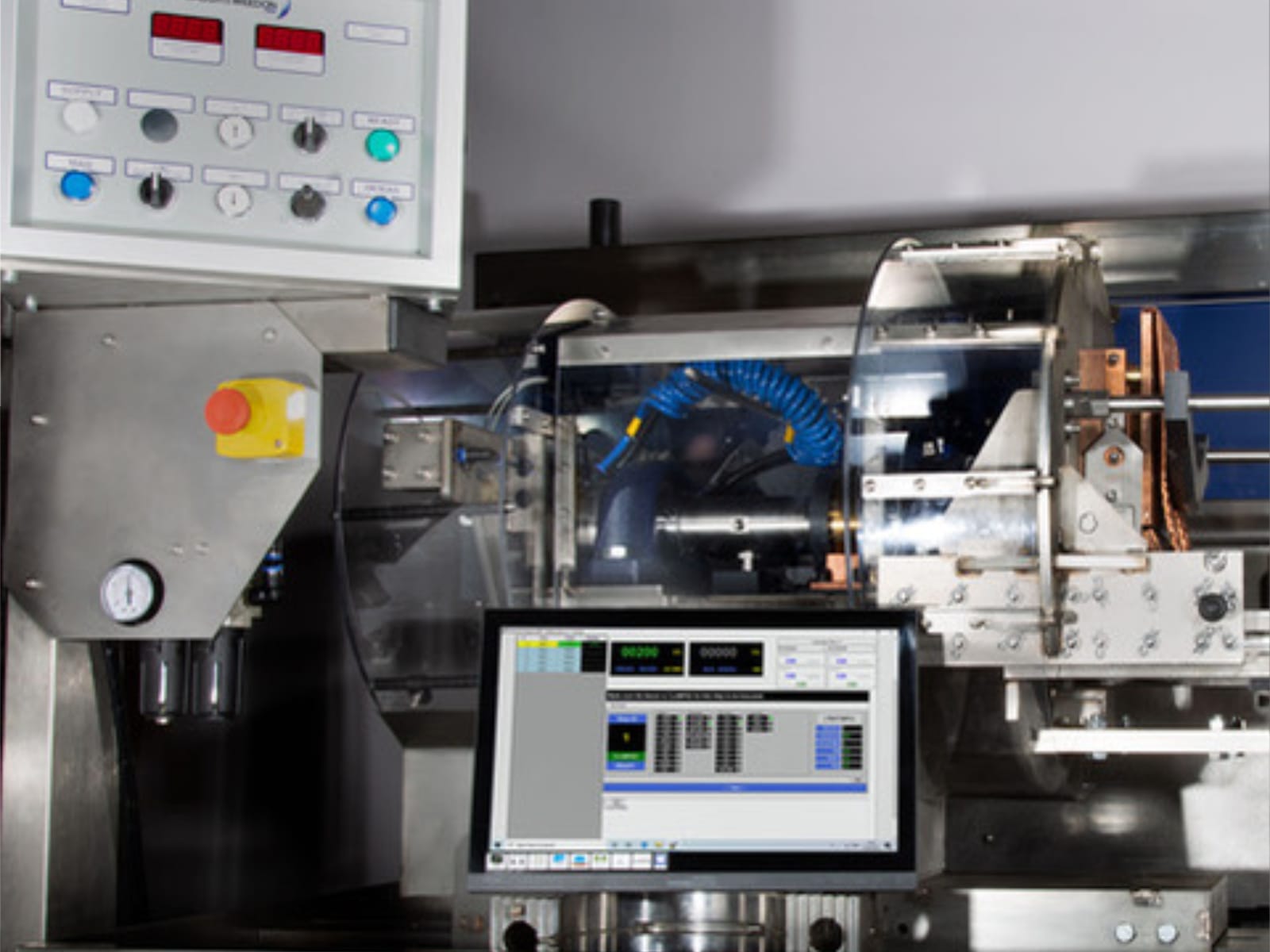

EBU

Our MPI benches are available in standard sizes or built to your dimension specifications; with a wide range of magnetising modes and current waveforms, supported by a full range of accessories and ancillary equipment from Baugh and Weedon. Designed and produced in Hereford, UK, the MAGAZON Bench series offers MPI solutions for the testing for components, of all sizes, that require substantial magnetising currents.

Advantages of our EBU Extended Benches include:

- All benches can be customised to meet your application needs

- Stainless Steel Construction

- Footswitch operations

- Power pack upgrades available to achieve maximum Amp output

- Control Panels built to fit with your inspection process

- Suitable to use with water-based and kerosene inks

- Inking Systems available

- MAGLink2 option: enables PC Control of the MPI bench, enhancing procedural control

Overview

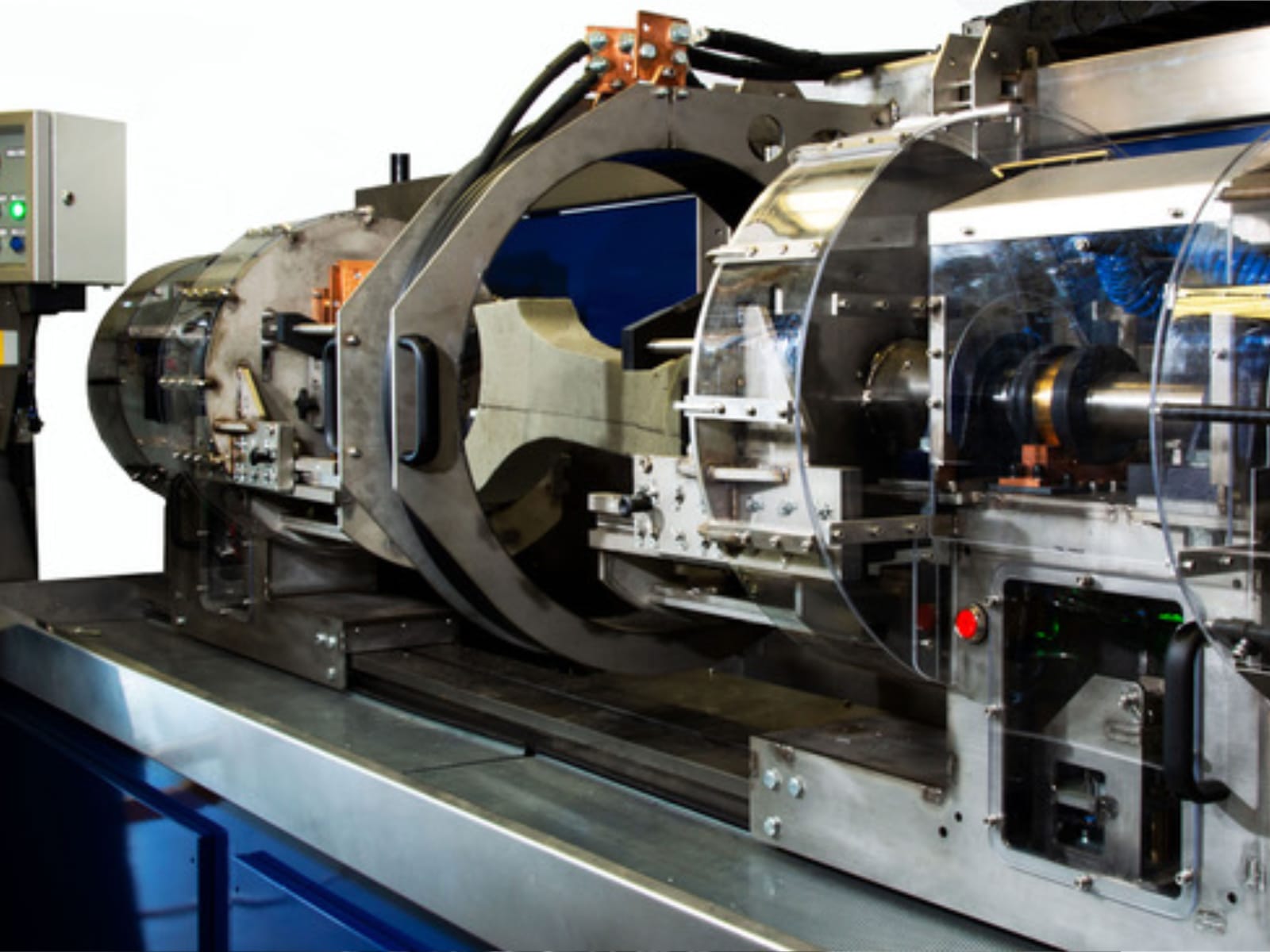

The EBU MAGAZON series of MPI benches offers operators “Extended” choices in the build and design, with a wider range of options that can be added. Our EBU MPI Benches deliver all the key features of the MAGAZON range via three series - EBU3, EBU5 and EBU6F. The EBU3 and EBU5 have 3000 Amp and 5000 Amp power packs respectively. The EBU6F delivers a 6000Amp (RMS) 3 phase, FWDC integral power pack, which can be upgraded to provide a maximum on 7000Amps FWDC.

A wide range of additional features can be fitted to or powered by a MAGAZON EBU series including Encircling Coils, Flux Coils, Special Coils, Remote Magnetising, Swinging Field, Test Piece Supports, Inspection Hoods. The EBU series can accommodate Component Test piece lengths from 1000mm - 3000mm long.

Download our brochure:

Magazon EBU (1.3MB)

Features

-

All benches can be customised to meet your application needs

-

EBU Series Power Pack Options include 3000, 5000, 6000

-

7000 Amps via power pack upgrade

-

Current flow and encircling coil magnetising

-

300 mm internal diameter coil

-

Coil Parking

-

Pneumatic clamping with footswitch operation

-

Remote magnetising via a footswitch

-

Automatic demagnetising using AC decay

-

Thyristor current control with current pre-selection

-

Pre-set shot time

-

50L Free standing stainless steel reservoir with pumped ink recirculation

-

Control console mounted above the headstock

-

Test piece lengths: 1000mm - 3000mm

Videos

Standard Kit

-

EBU Bench - Standard Build or designed to meet your specification

Options

- Selectable shot time 1, 2 and 3 seconds

- Half wave rectified current (HWDC) waveform with max 2500 amps (2x mean)

- Flux flow magnetising using single phase FWDC

- EBU6F - upgradeable powerpack to 7000 Amps

- Variable transformer control available for sinusoidal waveforms

- Multi-directional magnetising thyristor control AC waveform

- Multi-directional magnetising thyristor control AC and HWDC waveforms

- Low current option, down to 100 Amps

- Encircling coils, Flux Coils, Special Coils

- Upgrade 300 mm coil with 400 mm coil

- UV Viewing Canopies

- Threader Bar adaptor

- Stand-alone power packs

- Automatic Sequencing

- Automatic Inking

Specification

| Standard Models | Options & Alternatives | |

| Power Pack | AC waveform with rated output currents as follows:- 1) 3 Series - 3000 A (RMS). 2) 5 Series - 5000A (RMS). Magnetic amperage selectable. | HWDC (half wave rectified) and single or 3 phase FWDC (full wave rectified) waveforms. |

| Current Flow Magnetising | Max nominal outputs AC:- 1) 3 Series - 4200 A (peak) 2) 5 Series - 7000A (peak) measured through a standard shunt. Carriage mounted, 5 tum, 300mm to 600mm ID, length 120mm. | Max nominal outputs HWDC: 1) 3 Series - 4200 A (peak) 2) 5 Series 7000 A (peak) measured through a standard shunt. SBU: Max output nominal 2800 A FWDC (peak) 3) Current (amperage) “on” safety indicator light. |

| Encircling Coil Magnetising | Carriage mounted, 5 tum, 300mm ID coil, length 100mm. Magnetising: Nominal maximum output/centre field strength in an empty coil. 1) 3 Series - 6000 A/T AC (RMS) / 34 kA/m 2) 5 Series - 9000 A/T AC (RMS) / 47 kA/m 3) 6 Series - 12500 A/T (Mean) with Quick Break Coil can be parked at either head or tailstock, or folded away. | Alternative sizes 400, 500 and 600mm ID. |

| Flux Flow Magnetising | n/a | Head and tailstock integral flux coils powered by AC, HWDC, single or 3-phase FWDC. |

| Multi-Directional Magnetising | n/a | Swinging Field: Simultaneous operation of two Magnetising: magnetising circuits, to produce a “swinging field” or rotating vector. |

| Current Control System | Variable thyristor, with resulting complex waveform. Control System: Manufacturer’s proprietary system. | A variable transformer can be fitted to provide a sinusoidal current waveform. Control System: Programmable Logic Controller. |

| Working Range | Current range: 10% to 100% of maximum output. | Extended working range subject to requirements. |

| Metering | Digital metering, calibrated to display PEAK, RMS or 2 x MEAN, within 5% over working range to meet customer requirements. | AC output displayed as rms (variable transformer only). HWDC and FWDC output displayed as peak. |

| Shot Time | Pre-set single shot of 1, 2 or 3 seconds (other timings can be accommodated). | Any shot-time combination can be catered for, including multiple shots. |

| Duty Cycle | Dynamic duty cycle from 20% at maximum output, to 100% at around 1000A PEAK. | n/a |

| Max “ON” Time | 3 seconds at 20% duty cycle. | n/a |

| Demagnetising | Automatic decaying AC DEMAG. | FWDC DEMAG: Low frequency, reversing polarity, current step-down method. |

| Headstock | Pneumatically operated, manual control. Clamping stroke: 25mm. Flexible Copper Contact pads: 160mm x 160mm, with V-Block. | Special designs of faceplate and contact pads available. |

| Tailstock | Fully adjustable, manual positioning over entire bed length. Manual quick release locking mechanism. | n/a |

| Testpiece Support | V-blocks on head and tailstocks. | Integrally mounted roller supports. Removable small. piece device for rotating delicate components. Bed bar mounted adjustable supports. |

| Inking System | Ink Tank: 13.2 (US gal) stainless steel (covered) reservoir with external re-circulating pump, manual application & integral controls. Magnetization Activation: foot switch and panel button. Manual application gun, with ergonomic trigger. | utomatic inking as part of the automated process sequence. Magnetization Activation: Hip/push bar or wireless remote or two-handed safety switches. |

| Services: Power Supply | 380/415V 50 Hz, 3 phase + neutral + earth, current drawn as follows: 1) 3 Series - 100A max. 2) 5 Series - 200A max. | 3 phase supplies between 200 - 650 volts, 50/60Hz units can be supplied. |

| Air Supply | 6 bar. (FR unit fitted as standard). | n/a |

| Manufacturing Standards | CE Certified. | Manufactured to further International Standards, details available on request, e.g. UL, CSA. |

Specification subject to change without notice.

Dimensions

| Max Testpiece | |||||

| Length (mm): | 1000 | 1500 | 2000 | 2500 | 3000 |

|---|---|---|---|---|---|

| Weight (kg): | 250 | 250 | 250 | 250 | 250 |

| Equipment Dimensions | |||||

| Width (mm): | 2000 | 2500 | 3000 | 3500 | 4000 |

| Depth (mm): | 850 | 850 | 850 | 850 | 850 |

| Height to bed bar (mm): | 885 | 885 | 885 | 885 | 885 |

| Bed to pad centre (mm): | 430 | 430 | 430 | 430 | 430 |

Related Products