Partner Products

Triton 1000 Series

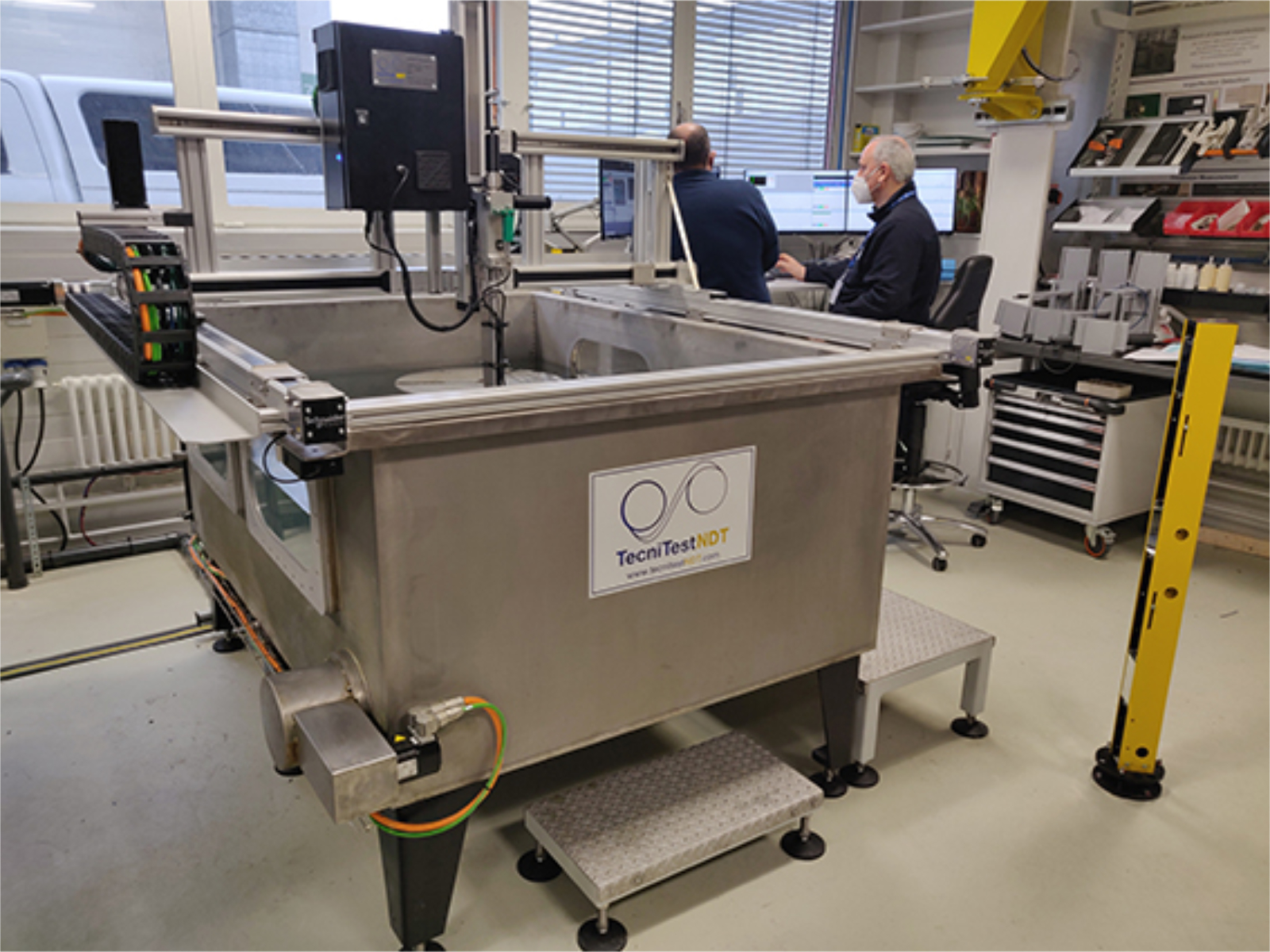

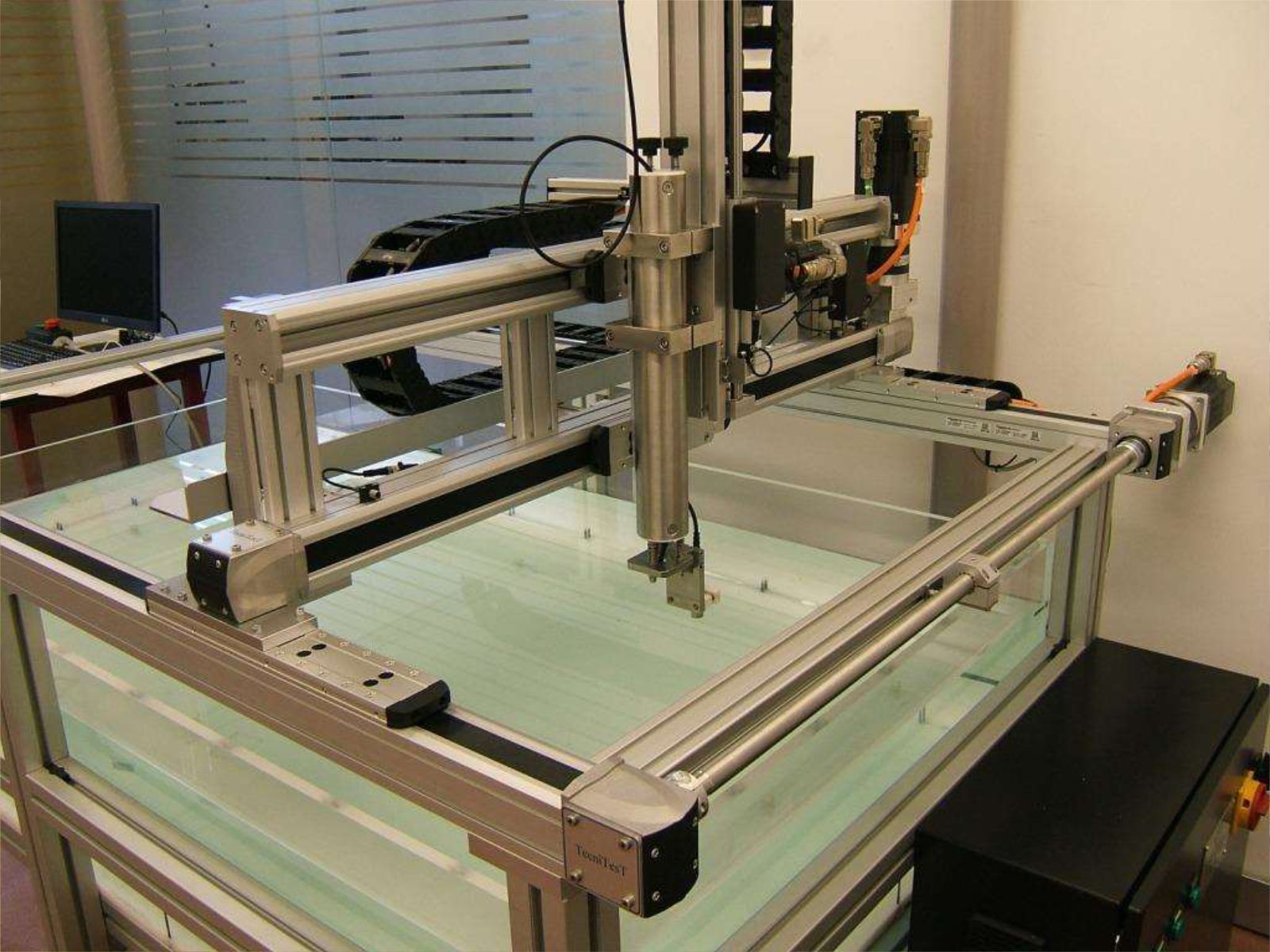

Tecnitest NDT design and build a complete range of reliable and high performance ultrasonic immersion tanks, Triton Series, which can be used can be used for industrial Non Destructive Testing (NDT) applications, research projects and training. The modular design of the ultrasonic immersion tank systems allows upgrading, easily matching dimensional, kinematic and technique related specifications.

Advantages if the Triton 1000 Series include:

- Fluid inspection of 3D complex geometries

- 100% component inspection in one pass, du to 7 phased array probes with with 128 elements. Up to 896 for complex configuration

(Related Products: UT Scanners)

Overview

In the manufacturing processes of the aeronautical sector, the use of composite materials is frequent practice allowing great advances which is rapidly spreading to other fields. The high-quality standards in wrong with these types of advanced materials require a 100% assured quality control of the structural parts, before they are submitted to assembly and final production. For conventional ultrasonic testing, single-element probes are used to generate an ultrasonic signals for material inspection. However, when inspections are done on composite materials, phased array probes (PA) are now being used to detect component failures, determining quality levels far me rapidly. Tecnitest’s Robotic system has automatic trajectory tracking, applying Pulse-Echo and Double Transmission techniques with Phased Array technology, as well as TT transmission, with water coupling via immersion tanks, so that it is possible to inspect one hundred percent of monolithic structures of solid laminates and sandwich structures.

Download our brochure:

Tecnitest Immersion Tanks (203.1KB)

Features

- Stiff extruded free standing aluminium frame (black panel covered)

- Belt and/or ball bearing drive axis with position accuracy better than ±0.1 mm depending on the size of the tank and the accuracy required

- Independent Perspex or Stainless-Steel tank, depending on the size of the tank

- Bottom glass with adjustable supports for double through transmission tests

- Interchangeable probe holder, manually adjustable (0º-90º XZ or YZ) and additional fine adjustment of relative probe position

- Scanning speed up to 500 mm/s (linear axis X, depending on the actual total length)

- Optional: external axis (turn) attachment and support (Z or X direction)

- From two up to eight motorised axes (standard), expandable. Axis with traction through pinion, rack, or belt

- High accuracy movement to ± 0.1mm with a minimum index of 0.1mm

- Optional contour following equipment

Standard Kit

UT Scanning Systems are designed and developed around the inspection application and therefore all be unique to each customer.

Options

The Triton range of systems comprises a series of immersion tanks for ultrasonic inspection with the following standard dimensions (scan lengths), up to 15 m length (X axis). Specific requirements can be considered.

| Triton 400 | 400mm x 400mm x 250mm |

|---|---|

| Triton 800 | 800mm x 400mm x 250mm |

| Triton 1000 | 1000mm x 800mm x 300mm |

| Triton 1500 | 1500mm x 800mm x 300mm |

| Triton 2000 | 2000mm x 800mm x 300mm |

Specification

| Mechanics | From 2 up to 8 motorized axis (standard), expandable Axis with traction through pinion, rack or belt High accuracy movement to ± 0.01mm with a minimum index of 0.1mm Optional tools for inspections |

|---|---|

| Electronics | Control of movement made by commercial equipment to facilitate maintenance Index adjustable from 0.1mm (depending on model) Programmable speed to 500 mm / s Possibility of inspection in various planes |

| Software | Software of system based on Windows Software up-datable by via Internet Friendly interface easy to use Fast programmability for self-learning A-SCAN in real time on screen Programmable Speed and Index Creation of bitmap files Complete file of inspection data Sending of results through Internet Evaluation in real time by local network |